| |

|

|

Delivering Advanced Engineering Solutions |

|

|

|

|

|

|

|

|

From Failure Rate calculation, MTBF analysis and beyond, our engineers are ready to help you achieve your Reliability goals.

| Reliability Prediction |

|

Life Data Analysis |

|

System Reliability |

| MIL-217 |

|

Weibull |

|

Reliability Block Diagram |

| Telecorida |

|

Bayesian |

|

Fault Tree |

| RDF 2006 |

|

|

|

|

| NSWC 98 |

|

|

|

|

AESC brings years of experience and expert staff that specialize in multitude of RMA analysis techniques and methodologies. AESC has utilized its expertise during design, prior to and after commercial distribution, to assess reliability, maintainability, and availability of products, and systems. Our belief is that high reliability, and high availability systems inherently increase safety.

AESC performs reliability analysis prior to commercial distribution utilizing theoretical and statistical methods by determining reliability of each component, then progressively moving upward, to determine reliability of each subassembly until system reliability is determined. This assessment is recommended when field and service data is not available, ultimately if a system has been in service or has had actual tests in the intended environment, that data will take precedence.

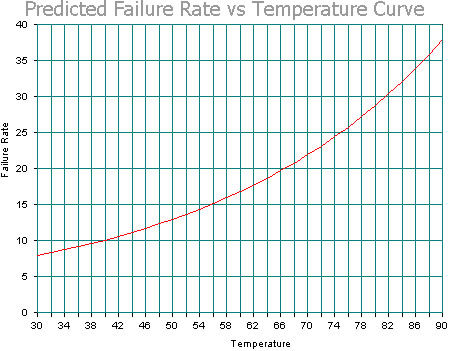

The following curve is an example of an electronics system reliability prediction showing the effects of temperature variation on failure rate. During design this assessment helps guide the development towards higher reliability, and provides the analytical means to optimize the "cost-reliability" trade off.

|

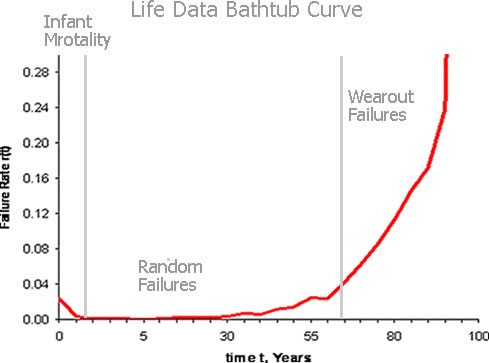

The following curve is an example of a reliability assessment using field data, showing failure rate variance over time. It shows three distinct life cycle phases of initial deployment, steady state operations, and end of life of the system.

|

|

|

|

|

|

|

|

|